Absenteeism affects every business operation. If someone isn’t there to do their job, the tasks are either delayed or another person has to be found to fill in. Direct costs include the expense of paying out sick leave plus replacement staff. Indirect costs are seen in delays of work and the effect of the absence on coworkers or supervisors. Costs begin to add up and affect the bottom line. In Australia, the annual cost of absenteeism to the Australian economy is estimated at $44 billion per year.

But, through the use of existing data, absenteeism can be predicted and potentially prevented.

In our last article, we went over the compounding effect of data and it’s three components: hindsight, insight and foresight. To sum up, as the use of your data is optimised, you move from assessing what happened and why to predicting what will happen. You are able to see what actions you can take to ensure a favourable outcome. Your existing data is optimised and gives you the ability to make better decisions and better decisions lead to better business.

Absenteeism is one key area that we can assess with the compounding effect of data to better understand why it happens and prevent it from happening in future, resulting in a significant reduction in cost.

Predicting absenteeism in the Meat Industry

Labour-intensive operations where consistent staffing is key to keeping up with output are most affected by absenteeism. Australia’s Meat Industry employs over 32,000 people and is a $21 billion-dollar industry. An analysis done by the Australian Meat Processor Corporation found that labour makes up 58% of the operating cost for beef processors. With absenteeism a major issue in the meat industry and labour costs comprising a significant portion of the cost of meat, processors should be particularly motivated to control absenteeism.

By utilising the compounding effects of data, absenteeism can be accurately forecasted and potentially prevented to increase efficiency and reduce cost.

First, by applying Descriptive Analytics to existing data we can extrapolate the rates and costs of absenteeism. This is the hindsight step – looking at what happened. It’s a basic assessment of how often and where absenteeism is occurring and the associated costs.

Then by using Diagnostic Analytics we uncover why it occurred – this is the insight component. Illness or injury, stress, family issues, transport issues and even employee morale can all be reasons for absenteeism. Analysis of data can pinpoint departments, divisions or geographic locations, all creating a picture of the reasons behind the occurrence.

Finally, we head into the foresight component of the compounding effects of data, where we apply Predictive Analytics to predict when absenteeism will occur, based on what we have already learned about the rates and the reasons. The ability to forecast when it occurs means you now have the ability to take action to prevent it from occurring.

Preventing absenteeism has a significant effect on labour cost while increasing production and keeping customers satisfied. Australia’s meat industry would see a major benefit by using their existing data in the most effective way through the application of Decision Intelligence solution.

Getting started with data

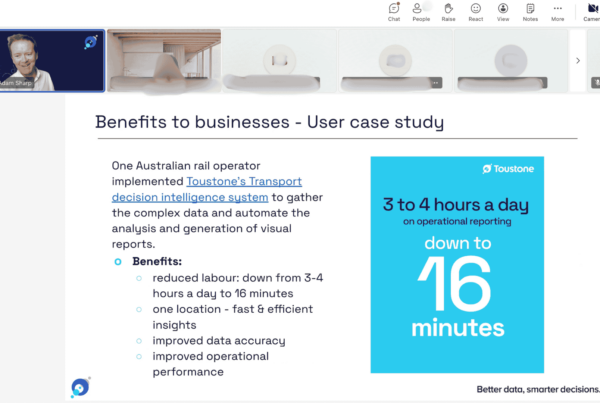

At Toustone, we are dedicated to help businesses make effective use of their existing data in order to grow. Our reporting solution delivers simple, automated dashboard reports identifying trends, costs, and insights, enabling you to make the best decisions without wasting your time on gathering and analyzing data.